Developing vaccines has historically been a time-consuming process, often taking more than a decade. That’s in part because there are so many phases, each playing an integral part in helping to save lives around the world.

One exciting way GSK are continuing to innovate is by using a digital technology known as a ‘digital twin’ to speed up the entire vaccine development process.

Why traditional vaccine development can take long

Traditional vaccine development and production progresses through many phases, with few digital connections between them. These include:

- Understanding the pathogen via genetic sequencing and other methods

- Selection of the best vaccine candidate

- Extensive preclinical testing, including proof of concept studies

- Development of the processes to manufacture the vaccine

- Robust in-human clinical trials to evaluate safety and efficacy

The evidence generated from the above forms the basis of the vaccine’s regulatory filing and approval. Once approved, the vaccine can then be manufactured and distributed at large scale – with significant lead time allocated to provide quality control.

By embracing digitalisation, GSK have identified a tremendous potential to optimise each phase of vaccine development and production. Working closely with Siemens and Atos, two of the world’s leading companies in digital transformation and technology, we have piloted a ‘digital twin’ – a complete and real-time simulation of the vaccine manufacturing process.

What is a digital twin?

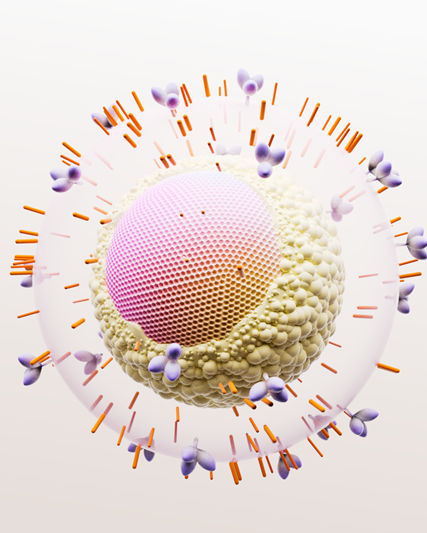

A digital twin is a virtual replica of a process, product, or service. When applied to producing vaccines, it collects real-time insights from the outset by combining the virtual and real realms of development and manufacturing in a closed loop. When the digital twin is connected to the real process, the physical sensors send data to the twin and the simulated insights are fed back to the control system, ensuring the vaccine manufacturing process operates at optimum level.

Think of it as a real-world experiment informing a computer-simulated (in silico) experiment, and vice versa, in a closed-loop so that both can become as efficient as possible. Such is the case in the automobile industry, where designs are often digitally modelled and tested in a multitude of ways on the computer before a car is ever driven.

This digital ’factory’ allows us to simulate, monitor closely, anticipate failures, and optimise quality and self-learning - ultimately allowing us to accelerate the vaccine manufacturing process and get vaccines to people much faster.

Operationalising digital twins at GSK

After successful completion of a proof-of-concept project with Siemens and Atos that focused on the production of particles of a vaccine adjuvant, GSK have gradually begun implementing digital twins into our development activities.

In addition to production, we are also exploring the potential of a digital twin to transform the process of vaccine R&D further upstream. This could be particularly beneficial earlier in a vaccine project, where the combination of high-throughput experimentation and the twin models would quickly produce the data needed to confirm theories. Looking ahead, a digital twin has the potential to drastically reduce real experimentation, in turn helping R&D to increase sustainability as fewer materials and less energy is consumed.

Through the use of Digital Twins, faster, less wasteful, more cost-effective vaccine development and manufacturing is possible. Which ultimately helps improve the health of millions of people around the world.